Submitted by Tight Spreads

The DOE has been flooding their sites with white-papers and latest Fusion Science and Technology Roadmap (FS&T Roadmap) are not just a scientific plan, but an industrial policy designed to transition fusion from the laboratory to the commercial market by the mid-2030s. The DOE has prioritized its actions to align with the aggressive “fast-track” development cycles of nuclear fission and fusion companies:

Near-Term (Next 2-3 Years): Digitalization & Infrastructure Prep

AI-Fusion Convergence: Launch the AI-Fusion Digital Convergence Platform to use machine learning to speed up materials discovery and predict plasma behavior.

Infrastructure Start: Build small-to-medium test facilities and complete the design for large-scale “First-of-a-Kind” (FOAK) facilities.

Regulatory Frameworks: Finalize licensing and safety standards to give investors, consumers, and citizens alike certainty on how these plants will be regulated.

Mid-Term (3-5 Years): Prototype Integration

Pilot Plant Construction: Support the private sector in constructing the first fusion pilot plants (FPPs).

Fuel & Materials Testing: Delivery of integration platforms for testing tritium fuel cycles and materials under intense radiation.

Supply Chain Seeding: Support domestic manufacturing for high-heat components and superconducting magnets.

Long-Term (5-10 Years): Grid Delivery & Scale-Up

Commercial Operation: The first fleet of pilot plants begins delivering power to the grid.

Commercial Maturity: Expand public infrastructure to support a global market, focusing on lowering the levelized cost of energy to make fusion competitive with other generation technologies today.

The Six Core Technical Challenge Areas

These are the gaps the DOE is prioritizing through its public research budget to ensure relevant companies succeed.

Structural Materials: Developing metals that won’t become brittle or weak after years of intense neutron bombardment. Metals such as Reduced Activation Ferritic Martensitic (RAFM) steels can withstand intense neutron damage without swelling or becoming brittle.

Plasma-Facing Components (PFCs): Creating “first walls” that can survive heat fluxes equivalent to the surface of the sun.

Confinement Systems: Optimizing magnets and lasers to hold the superheated fuel stable for long periods. Relevant companies: BRKR, COHR

Fuel Cycle & Tritium Processing: Establishing a closed loop fuel system to breed, recover, and recycle tritium fuel, as it is extremely scarce in nature. Relevant companies: OKLO, ASPI, BWXT

Blankets: Engineering the wrapper around the reactor that captures heat for electricity and breeds the fuel.

Plant Engineering & Integration: Linking a fusion reactor to standard turbines and maintenance via robotics. Relevant companies: NVDA, IBM

To grasp the next frontier of the energy transition, we need to distinguish between the nuclear power we use today and the “holy grail” of energy: Nuclear Fusion. Nuclear fusion is the process of combining two light atomic nuclei to form a single, heavier nucleus. This process releases a massive amount of energy as it typically uses two hydrogen isotopes for fuel: Deuterium and Tritium (D-T fuel). Nuclear Fission is the splitting of heavy atoms, such as the current method of commercial nuclear power plants with Uranium.

What is Plasma?

We are typically taught that there are three states of matter: solid, liquid, and gas. Plasma is the fourth state, and it is the most common form of matter in the visible universe. Plasma is created when a gas is heated to such extreme temperatures that the electrons are stripped away from their parent atoms. This results in an “ionized” gas—a hot, soup-like mixture of free-moving positively charged nuclei (ions) and negatively charged electrons. It is highly conductive and can be manipulated and shaped by magnetic fields. This characteristic is the lynchpin of modern fusion reactor design.

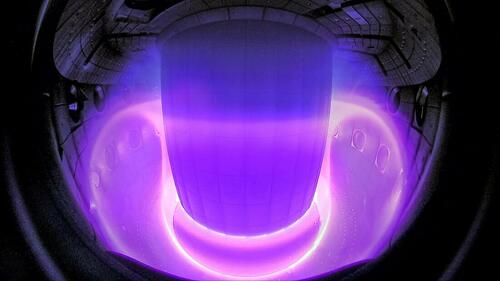

Plasma in a fusion fusion reactor:

Plasma’s Significance in a Fusion Reactor

In a fusion reactor, plasma is not just a byproduct; it is the reaction medium itself. It plays three critical roles toward enabling fusion energy:

The Coulomb Barrier: Atomic nuclei are positively charged and naturally repel one another. To overcome this “Coulomb Barrier,” the fuel is heated into a plasma state, providing the extreme kinetic energy necessary for the nuclei to collide and fuse.

Magnetic Confinement: Because no physical material can withstand fusion temperatures (upwards of 150 million degrees Celsius), the plasma must be suspended in mid-air. Scientists use the plasma’s electromagnetic properties to hold it in place using powerful superconducting magnets.

Self-Sufficiency: The ultimate goal is to achieve a burning plasma. This is a self-sufficient state where the heat generated by the fusion reactions themselves maintains the required temperature, eliminating the need for external heating.

Plasma as a medium in a Tokamak Fusion Reactor:

The Role of Materials in Fusion Architectures

Structural materials form the physical vessel and internal supports of a fusion plant. Materials must withstand unprecedented neutron flux, high thermal loads, and corrosive environments while maintaining the precise vacuum required for plasma stability.

Materials that are prioritized include Reduced Activation Ferritic Martensitic (RAFM) steels and vanadium alloys. These are engineered to minimize long-lived radioactive waste, ensuring that the structural “backbone” of either machine doesn’t remain hazardous for centuries after the plant is decommissioned. Easily produced RAFM steels and vanadium alloys strategically provide supply chain independence, dual-use applications in defense and aerospace, and enable closed fuel cycles to enhance commercial viability.

Plasma-Facing Components (PFCs) & Interactions

PFCs are the “first wall” materials that directly interact with the 100-million-degree plasma. They must exhaust extreme heat without contaminating the reaction. Tungsten, a critical material for PFCs, is a key focus of domestic mineral security.

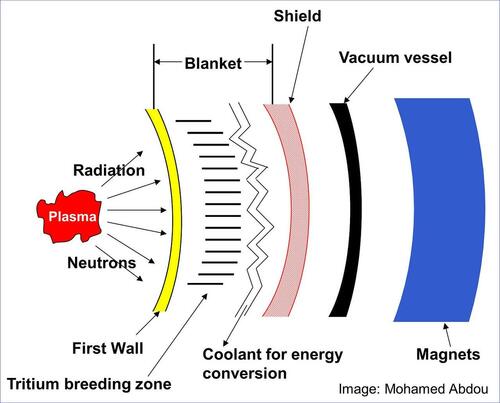

Layers of a fusion reactor:

Magnetic and Inertial Confinement Fusion

The DOE’s FS&T Roadmap follows a dual-track approach pursuing two distinct methods to contain fusion: Magnetic Confinement Fusion & Inertial Confinement Fusion.

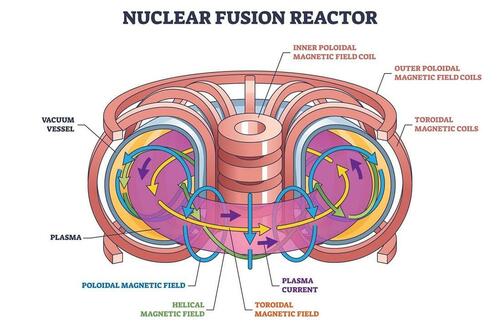

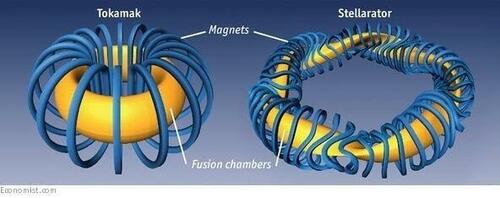

Magnetic Confinement Fusion: This method utilizes High-Temperature Superconducting (HTS) magnets to create powerful magnetic “bottles.” These magnets suspend and stabilize the superheated plasma, preventing it from touching the reactor walls. There are two primary magnetic confinement architectures: Tokamaks and Stellarators:

Tokamaks: These are doughnut-shaped devices that use a combination of external magnets and an internal electrical current flowing through the plasma to maintain stability.

Stellarators: These use a complex, twisted ring of external coils to confine the plasma without needing an internal current. While more stable than Tokamaks, the geometry of a Stellarator is very intricate.

Companies that produce HTS magnets that make compact fusion possible:

Bruker Corporation (NASDAQ: BRKR): Known for scientific instruments, BRKR additionally serves as a critical industrial partner to the DOE through its subsidiary Bruker Energy & Supercon Technologies (BEST). BEST is known for its the stewardship of HTS magnet technology engineering. In the pursuit of next-generation energy solutions, BRKR has been a critical supplier of advanced Niobium-Tin and High-Temperature Superconductor (HTS) conductors for several high-stakes DOE initiatives: fusion energy, accelerator upgrades, and NMR proving grounds (relevant for testing the accuracy of isotope purities).

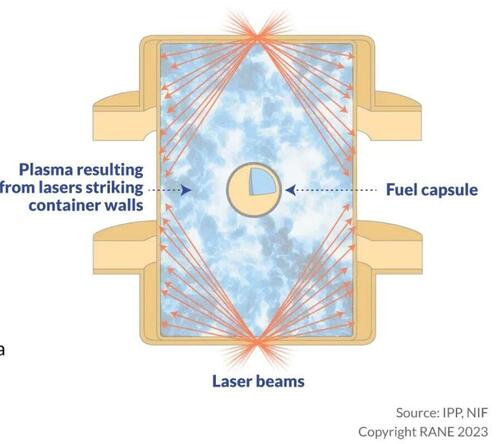

Inertial Confinement Fusion: This approach takes a “pulsed” path, using high-energy lasers to rapidly compress tiny fuel pellets. This intense compression triggers a series of micro-explosions that ignite the plasma, creating a steady stream of energy production similar to the internal combustion of an engine.

Inertial fusion requires pulsed lasers of incredible power and precision. The companies that build the optical components and high-power diodes are the primary enablers:

- Coherent Corp. (NYSE: COHR): A critical business in this sector. Their LEAP excimer laser platform is actually used by REBCO manufacturers to deposit the superconducting layers onto the tape. Furthermore, they provide high-power diode lasers essential for pumping the large-scale lasers used in fusion experiments.

- Syntec Optics (NASDAQ: OPTX): A U.S.-based manufacturer of precision optics. They provide the specialized lenses and mirrors required for high-energy laser systems.

Inertial Confinement Fusion:

The race for fusion is one of the key drivers for the U.S. massive push to securitize a domestic rare earth and advanced materials supply chain. A primary driver is the production of HTS magnets, which rely on Rare-Earth Barium Copper Oxide (REBCO). These specialized materials allow for more compact and efficient fusion reactors, but their utility extends far beyond energy; REBCO technology is also essential for next-generation MRI machines and high-speed maglev rail systems.

The Fuel Cycle & Tritium Breeding

The DOE is pursuing a “closed-loop” fuel cycle where fusion and fast reactors breed their own tritium fuel using lithium-containing blankets. Because tritium is rare and radioactive, the FS&T Roadmap emphasizes advanced accountancy and Direct Internal Recycling to minimize inventory. The DOE is prioritizing Tritium as a vital material for the U.S. nuclear stockpile, critical for national defense and nonproliferation. Establishing a domestic supply of light isotopes—specifically Lithium-6, Tritium, and Deuterium for fusion breeding and fuel—ensures that the U.S. does not depend on international sources for its most critical nuclear assets.

Companies that are produce light isotopes and/or have breeder reactor capabilities include:

ASP Isotopes (ASPI): ASPI hopes to contribute to Li-6 supply in 2026/2027, as mentioned in their shareholder letter from September of 2025:

“There is a considerable amount of customer demand for HALEU, as well as Lithium-6 and Lithium-7. We expect to have the first Lithium-6 plant operational during 2026, subject to the timely receipt of all required permits and licenses.”

BWXT & The Tennessee Valley Authority (TVA): As of late 2025, TVA has emerged as the primary “Tritium Hub.” Leveraging their experience producing Tritium for the nuclear stockpile at Watts Bar, TVA is exploring the use of the BWRX-300 SMR to host Tritium-Producing Burnable Absorber Rods. By replacing standard neutron absorbers with lithium-based rods, these SMRs can “harvest” Tritium as a byproduct of normal electricity generation.

Oklo (Aurora Powerhouse and Atomic Alchemy): While Oklo’s primary Aurora powerhouse is a fast fission reactor capable of breeding tritium, its radioisotope pilot facility and VIPR technology have capabilities inclusive of producing specialized the “light isotopes” used in the breeder blanket and fuel. As of early 2026, Oklo’s subsidiary, Atomic Alchemy, has transitioned into active execution under a DOE Other Transaction Agreement (OTA) to fast track their radioisotope business and production.

TerraPower (Natrium): As a similar reactor design to the Aurora Powerhouse, the Natrium reactor is an ideal candidate for isotope production. Fast reactors can irradiate lithium targets, potentially producing Tritium at a much higher rate than traditional light-water reactors.

Holtec (SMR-300): Holtec has positioned its SMR as a multipurpose tool. Their recent filings suggest that their reactors at the Palisades site could be configured with specialized “target” assemblies to produce various isotopes, including Tritium, for both commercial fusion and medical use.

Blanket Science and Technology

The blanket of a reactor in the latest FS&T Roadmap has been reimagined as the “Energy Engine” of the fusion power plant. While the plasma provides the environment for the reaction, the blanket is the critical interface where that reaction is converted into tangible products: usable heat for the electrical grid and essential fuel for the reactor’s continued operation. This massive component surrounds the fusion core and serves three non-negotiable functions:

It facilitates energy conversion by capturing high-energy neutrons—which carry approximately 80% of the fusion energy—and converting their kinetic energy into thermal heat.

It enables tritium breeding by using those same neutrons to strike lithium-6 atoms, transmuting them into Tritium.

It acts as a radiation shield, protecting delicate superconducting magnets and exterior plant components from intense neutron flux to ensure structural longevity.

One of the most significant strategic shifts in the 2025 Roadmap is the explicit move to leverage advanced fission R&D to accelerate these fusion milestones. The molten salts used in fusion blankets are nearly identical to the coolants required for Generation-IV Fission Molten Salt Reactors. By aligning these technologies, the DOE is creating a unified domestic supply chain where purification systems, high-temperature pumps, and specialized alloys developed for advanced fission can be utilized directly in the fusion sector.

Plant Engineering & Systems Integration

This challenge focuses on the Balance of Plant (BOP)—the turbines, heat exchangers, and robotic maintenance systems that turn a “fusion engine” into a grid-ready power plant. The priority is reliability, availability, maintainability, and inspectability. Here, the AI-fusion digital convergence becomes the primary tool. AI-enabled “Digital Twins” will manage the plant’s complex systems in real-time, just as they optimize hyperscale data centers today. This creates a massive opportunity for the AI ecosystem; companies like NVIDIA and IBM are already leading efforts (such as Stellar-AI) to provide the supercomputing clusters needed for these simulations.

Many often focus on the “Fusion Core,” but the Balance of Plant is where 50% of the capital cost lives. This is the traditional engineering—turbines, heat exchangers, and cooling systems—that turns heat into electricity. Standard steam turbines may not be efficient enough. This requires innovations such as Supercritical CO2 turbines which are developed by only a handful of agencies and almost exclusively by Oklo commercially. These turbines are smaller and more efficient than steam, and are being prioritized to keep the plant footprint small.

* * *

Read more at the TightSpreads substack

Loading recommendations...