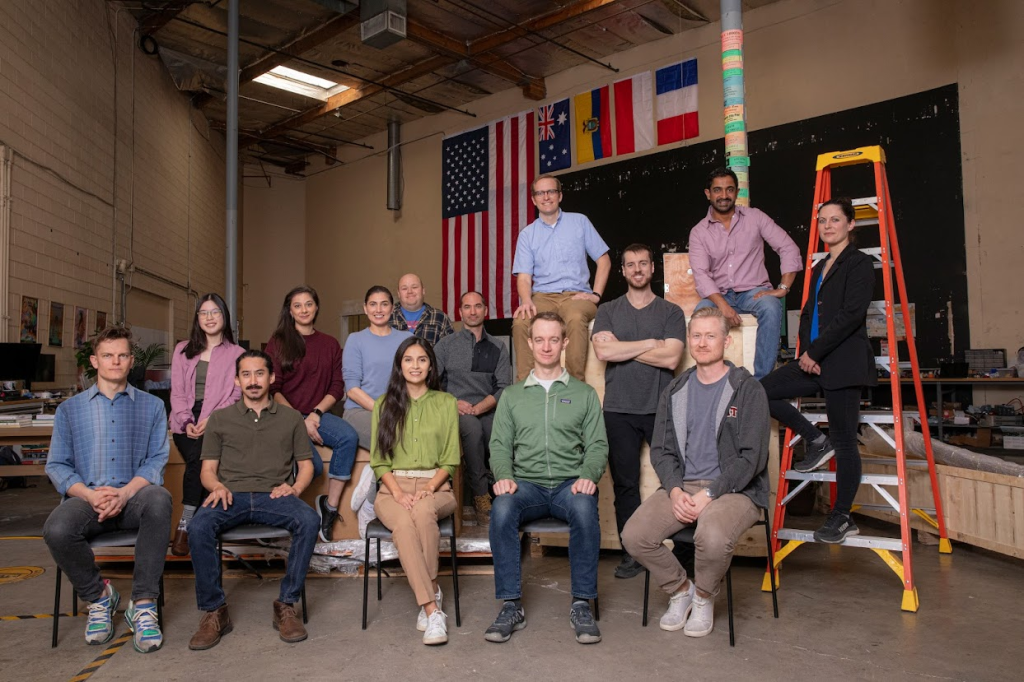

We did it! After two years of hard work we hold in our hands hard proof that the incredible team at Terraform can make synthetic natural gas from sunlight and air, as reported in TechCrunch.

Last Wednesday March 27, 2024, we commissioned our integrated power-to-gas demonstrator. The system converts electricity and air into affordable fossil-free natural gas using proprietary subsystems, developed in-house, for hydrogen electrolysis, direct air capture, and methanation. This marks a major milestone in the technical and commercial development of our technology and another step on the path to our positive vision for the future where everyone has access to plentiful cheap, reliable energy, harvested from renewable carbon and power, with lower ecological and climate impact.

Our core innovation is the utilization of proven and well-understood industrial processes implemented within innovatively simple and cost-effective proprietary technology systems adapted to the daily variations of renewable power for producing cheap sustainable natural gas from sunlight and air. These design and process innovations are responsible for driving production costs down for both their green hydrogen and atmospheric CO2 capture to levels previously thought unattainable. Combining super-cheap solar power with low-cost green hydrogen and CO2 capture are the key to producing commodity-grade electro-fuel alternatives at competitive commodity prices.

Our elite team of engineers have made significant progress towards our stated goals of radically cheaper green hydrogen and direct air capture CO2. We follow a simple playbook. Adapt a known industrial process to ultra-cheap solar power by a) radically reducing capex to compensate for lowered utilization and b) developing processes that are robust to variations in power due to weather, as well as diurnal and seasonal power shifts.

First, our innovative electrolyzer converts cheap solar power into hydrogen with current production costs at less than $2.50 per kg of H2. How? To first order, our electrolyzer capex costs <$100/kW, and we’re currently baselining solar PV DC electricity at $20/MWh. There is no hand waving about economies of scale or subsidies here, though we are eligible for the full IRA 45V green hydrogen tax credit, worth $3/kg-H2.

Second, the proprietary direct air capture (DAC) system concentrates CO2 in the atmosphere today for less than $250 per ton. How? Our DAC capex costs <$600/T-year-CO2. Like the electrolyzer, this represents a substantial improvement on the state of the art.

Finally, our in-house multistage Sabatier chemical reactor ingests hydrogen and CO2, producing pipeline grade natural gas, which is >97% methane (CH4). Our reactor uses no rare or expensive catalysts nor cherry-picked data – it handily operates for hours in steady state.

The Terraformer combines these three subsystems into one modular chemical plant, skid-mounted for deployment alongside a solar PV array.

It is particularly cool to develop and build all three of our sub-systems in our castle in Burbank, CA, right across from the long-time home of the fabled Lockheed Skunk Works. In-house production & manufacturing enables faster iteration, lowered supply chain risk, and the successful demonstration of the complete techno-economic model for producing cost-effective fossil-free natural gas.

While I generally prefer understatement, it is hard to overstate the significance of this achievement, which has been two years in the making. Humanity today depends on traditional oil and gas to provide them with a cheap and easily transportable source of energy-dense hydrocarbons, to the tune of 100 million barrels per day, which unfortunately also generates ~50 gigatons per year of CO2 emissions.

The Terraformer unlocks an industrial-scale source of renewable hydrocarbons that breaks our dependence on fossil fuels and lays the foundation for another century of spectacular growth, broad-based wealth creation, and global environmental restoration.

What’s next? We’re taking reservations for our first production Terraformers, and ramping production to meet demand.