Authored by Eva Fu & Jan Jekielek via The Epoch Times (emphasis ours),

One flash is all it takes.

That’s how James Tour said the United States can tackle China’s rare earth dominance.

All he needs is discarded electronics—of which the United States has mountains. And from these scraps, the Rice University chemist and nanotechnologist has pioneered a way to quickly extract rare earth metals.

“We can pull out one metal and then the next,” he told The Epoch Times. “It’s really that simple.”

Tour’s solution is flash Joule heating: rapidly heating up the materials to thousands of degrees to vaporize the metals. Mixed with chlorine gas, the vapors turn into chlorides that emerge at different temperatures.

Just like in an incandescent light bulb, the technique works by passing an electric current through the raw material, Tour said. But whereas the former channels a steady electric current to create a perpetual glow, in treating metals, the energy arrives in short bursts, dialing up heat in milliseconds.

“Metals are infinitely recyclable,” he said.

And whereas the traditional way of distilling metals is rather “messy,” Tour said, what he proposes is all about simplicity—“you flash and you’re done.”

Speed is now more critical than ever. The United States is racing against time to reshore rare earth production, spurred in part by China’s October threat to dramatically curtail access.

With a one-year truce in hand, Washington now has a short window to close the gap. Getting a mine up and running can take 15 years.

Tour said his technology would put the United States on a faster track.

“It would give us a map to get independent,” he said.

“You can get these things going for a few tens of millions of dollars. That’s not very much when it comes to this type of manufacturing.”

US Dominance Lost to China

Rare earths, a subgroup of 17 critical minerals, are essential components in electric vehicles, wind turbines, smartphones, and missiles.

China currently sits at the center of this vital global production chain. It makes more than 90 percent of the world’s rare earth magnets, according to International Energy Agency data. China is also the sole supplier for certain elements, such as samarium, used in fighter jets and nuclear reactors for its high heat resistance.

This dominance comes from decades of strategic investment, lavish state subsidies, and aggressive market manipulation that stifled foreign competition.

Decisions made in the United States also played a part.

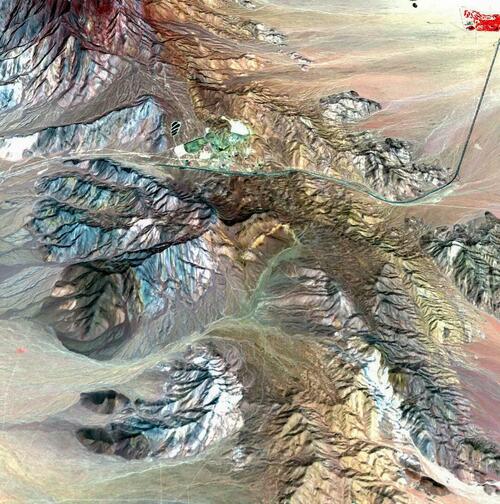

Until 1991, the country was a leading producer of rare earth minerals; the Mountain Pass mine in California supplied most of the world. Environmental troubles then shuttered the mine for years at the same time China began to gain a foothold.

Against the Pentagon’s objections, the U.S. government greenlit the 1995 sale of Magnequench, then the industry leader in rare earth magnets, to a Chinese front group, effectively handing over critical defense technology and manufacturing to China.

In 2004, Magnequench closed its Indiana plant and moved operations to China. Beijing started taxing exports of rare earth minerals the following year.

Twenty years later, the United States is beholden to Chinese minerals.

“We didn’t realize that we were selling something that turned out to be very important to our country,” Tour said.

Waste to Treasure

As early as 1976, the United States had a law regulating electronic waste disposal.

In the years that followed, the ballooning electronic waste created a whole recycling industry that still struggles to catch up. It’s now the fastest-growing type of waste, rising five times faster than recycling, according to the United Nations.

The United States produced 7.2 million tons of electronic waste in 2022—about one-eighth of the world’s total, the latest U.N. data show. That’s about 46 pounds for every American.

“We have these mountains of tailings that we can access, and we have these constant mountains of printed circuit boards,” Tour said.

Tour said that their method could clean up this spiraling nightmare of waste sites and turn it into a “treasure.”

Lucas Eddy, technology development manager for Metallium’s Texas subsidiary Flash Metals USA, said he is now seeing the idea being put into practice.

“The real reason a waste product is a waste product isn’t because it’s bad, it’s because it can’t be used,” he told The Epoch Times.

Here’s where flash Joule heating shines, according to Eddy, whose Texas factory has licensed the method for metal recovery.

Old Tech Reimagined

Joule heating—passing an electric current through a conductor to produce heat—has been around since the 1840s. It’s now an integral feature of every household, in toasters, electric heaters, ovens, and hair dryers.

Until now, no one had thought to use it for electronic waste.

The spark for Tour’s team began with reading a scientific paper describing using the flash Joule heating technique to make metallic nanoparticles.

The researchers tested the technique on carbon and found that it was a quick way to make high-quality graphene at low cost. They next began exploring its potential in extracting the much-needed rare earth metals.

Eddy, a 2025 Tour lab graduate, joined the project in early 2021 just as this shift began.

“It’s really live chemistry in action,” he said. “You see a rainbow of colors coming off.”

Each change of color represents one metal element that has separated out. Rare earths, usually with some of the highest boiling points, tend to come out last—often as a white powder, he said.

The project drew interest from the Defense Advanced Research Projects Agency, which asked them to make it more industrially applicable, Tour said. Under a federal contract, the team worked on lowering boiling points, experimenting with fluorides and chlorine in various forms, and eventually settled on chlorine gas.

That step was “revolutionary,” Eddy said.

Read the rest here...

Loading recommendations...