Chinese battery and vehicle makers are testing solid-state batteries on a small scale to drive growth, though technical challenges remain before mass adoption, Caixin reported days ago. Regardless, the path for the future of EV batteries seems clear.

These batteries, which use solid electrolytes, could revolutionize EVs by improving energy density, safety, lifespan, range, and charging time, easing "range anxiety" for drivers.

On Feb. 24, Mercedes-Benz began road-testing a lithium-metal solid-state battery from U.S. startup Factorial Energy, claiming a 25% longer range of up to 1,000 km per charge. However, verifying suitable materials remains a challenge, with sulfide-based electrolytes favored for conductivity but costly to produce. Other options include oxides, halides, and polymers.

AI may accelerate solid-state battery development by optimizing material selection and chemistry design, potentially overcoming current limitations.

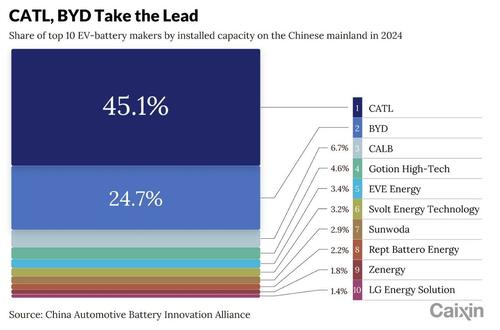

The Caixin report noted that global battery leaders like CATL, BYD, Toyota, and Factorial Energy are exploring sulfide-based solid electrolytes for next-generation batteries. Sulfides offer high conductivity and fast charging but are costly and reactive, posing fire risks.

Alternatives like polymers, oxides, and halides also have trade-offs, and researchers are experimenting with various materials to optimize performance. A major challenge is preventing interfacial cracks that reduce battery lifespan.

Current technology limits cracks to micrometers, far from the ideal nanometer scale. Labs use isostatic pressing to mitigate this, while Mercedes-Benz has integrated a pneumatic actuator in its test vehicle to adapt to volume changes.

AI is accelerating battery research by shifting material discovery from trial and error to data-driven predictions. High-throughput computing helps identify optimal materials, and companies like BYD and CATL are investing heavily in AI-powered R&D. BYD plans small-scale solid-state battery deployment by 2027 and mass adoption by 2030, while CATL is building a supercomputing center to enhance material selection and design.

As more automakers enter the race, the EV industry is evolving. Guangzhou Automobile Group aims to install in-house solid-state batteries by 2026, and SAIC Motor is investing ¥2.7 billion in battery maker QingTao to commercialize semi-solid-state cells.

Smaller suppliers may also benefit from redeveloping key components like binders and conductive agents. Despite their potential, solid-state batteries will likely coexist with liquid-state ones for years due to high costs and early-stage development. Their first uses may be in drones and robotics, where energy density and safety are critical.

Separately and unrelated to solid-state batteries, BYD Chairman and founder Wang Chuanfu unveiled a new EV charging system on Monday, claiming it can add 470 kilometers of range in approximately five minutes.

More range and quicker battery charging would be great.

Loading...